Source: thehindu.com

Hydroponic fodder promises to be the way to redeem dairy farmers faced with scarcity for quality cattle feed, especially for dairy farmers in urban areas who do not have enough land to cultivate the required quantity of green fodder.

Such farmers are dependent mostly on packaged cattle feed. Of course hydroponic fodder cannot substitute green fodder and hay completely, as it lacks in fibre content. But it is definitely a better substitute for packaged feeds.

The urban dairy farmers in Kerala are worried about the ever increasing price of cattle feed, and the lack of availability of green fodder. Shrinking land size in the state ensures lack of availability of green fodder and hay in sufficient quantities. The spiralling cost of packaged cattle feed adds to the cost of dairy farming. Hydroponic fodder provides an effective solution for both problems.

Kerala Dairy Development Department (KDDD), in Kannur and Thrissur districts, under its Integrated Dairy Development Project, has recently introduced a scheme to produce hydroponic green fodder. The department has already distributed 24 hydroponic fodder units to select diary farmers -14 in Thrissur and 10 in Kannur. V.S. Harsha, the Dairy Extension Officer (DEO), Thalipparamba Block, Kannur, claims that hydroponic fodder is more nutritious than the conventional green fodder and cheaper and safer than the commercially available packaged feeds. A judicious management of feed mixture per cattle is 25 kg of hydroponic fodder, 10 kg of conventional green fodder and five kg of straw per day per cow, which yields about 15 litre milk a day, suggests Ms. Harsha. Such a feeding programme can result in saving 20 to 25 per cent of daily feeding and working cost.

‘Hydroponics’ means the technique of growing plants without soil or solid growing medium, but using water or nutrient-rich solution only, for a short duration. The fodder production unit distributed by the KDDD has a greenhouse and a control unit. The greenhouse has tiered racks, each rack has rows of perforated trays for soaked seeds. Pipes fitted with micro-foggers above each tray ensures proper maintenance of required humidity and water fogging of the seed trays in the greenhouse. Tube lights provide optimal light requirement inside the greenhouse. The sensor-controlled unit regulates input of water and light automatically. Seeds like maize, barley and sorghum are used to grow fodder. The unit requires electricity round the clock.

The seeds are sown in a batch of 12 trays on a daily basis. Water and soluble nutrients are sprayed at regular intervals. Within six days the plants reach a height of 22 cm; they are then peeled off from the trays, and the fodder is now ready to feed the cattle.

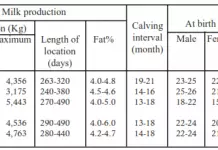

M.U. Pathrose, a farmer in Edakkom near Thalipparamba, has a unit installed at a cost of Rs.3 lakh, of which the department gave him Rs.1.75 lakh as subsidy. He produces 50 kg fodder a day. Pathrose gives 8.5 kg of hydroponic fodder per cow; he has six milch cows. He claims an increase of two litre of milk per cow per day, from 15 to 17 litres a day. Kerala Veterinary and Animal Sciences University Study indicates milk production increases by one to three litres per cow; in terms of quality also there is an increase of 0.3 percent in fat and 0.5 per cent in SNF, fetching better prices for the farmers.

Comments

comments