THE MANUFACTURE OF ETHANOL FROM WHEY

The whey from acid casein manufacture is unsuitable to be processed to lactose powder due to the presence of lactic acid and sulphate ions which interfere with the crystallisation process. However, although the whey is only 4 -5% lactose, this is still enough to cause a significant environmental impact. In New Zealand this whey is processed to produce ethanol, which is used in pharmaceuticals, perfumes and inks as well as beverages.

INTRODUCTION The disposal of whey is a worldwide problem. Large quantities of whey are produced as a by-product during the manufacture of cheese and casein, and this must be disposed of or processed in an environmentally acceptable way.

Since most of the components are of small molecular weight and soluble, they can quickly deplete oxygen levels in natural water systems: the COD (Chemical Oxygen Demand) of raw whey is about 60 kg m-3. The key to the utilisation of this resource has been changing the perception of whey from a ‘waste material’ to an ‘opportunity’ for further processing.

The success of the NZ Whey Corporation in turning whey products into a multi million dollar profit centre for the New Zealand dairy industry is evidence of the success of the change in perception. Deproteinized whey, or serum derived from the Whey Corporation plant, was seen as an opportunity for ethanol production.

Sweet wheys, such as those derived from the production of cheese, were already being used to make lactose powders (see article). Acid wheys from the production of lactic and sulphuric casein are not suitable for this (as they contain high levels of sulphate ions and lactic acid), but it was seen that they could be used to ferment the lactose to ethanol. The technology to process deproteinized whey into ethyl alcohol was developed in Europe about 20 years ago and was purchased from Ireland by the Anchor Ethanol Company in the late 1970s.

Since that time two plants have been established, at Tirau (using a continuous fermentation process) and Reporoa (using a batch fermentation process). The combined annual production of these two plants is 11 000 000 litres of ethanol. Two further independent distilleries based on whey have subsequently been built in New Zealand, producing an additional 6 000 000 litres.

The recovery of ethanol from a previously waste stream is a good example of technology being applied to rectify a problem. New Zealand now produces much more ethanol than is needed here and more than half of the total production is exported.

Export product is sold into markets as diverse as Sri Lanka and Japan, with the bulk of the product being used in beverages. The Anchor Ethanol Company continues to look for further opportunities to manufacture ethanol from lactose streams generated from new sites and other products.

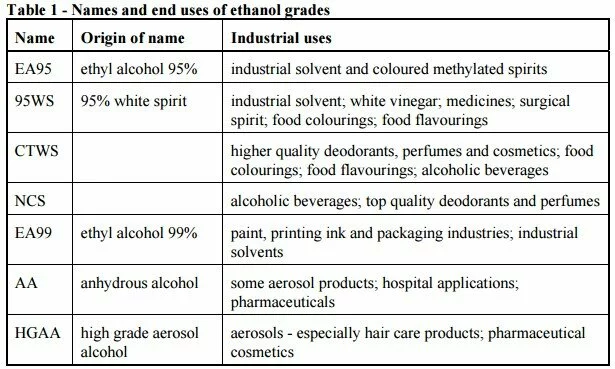

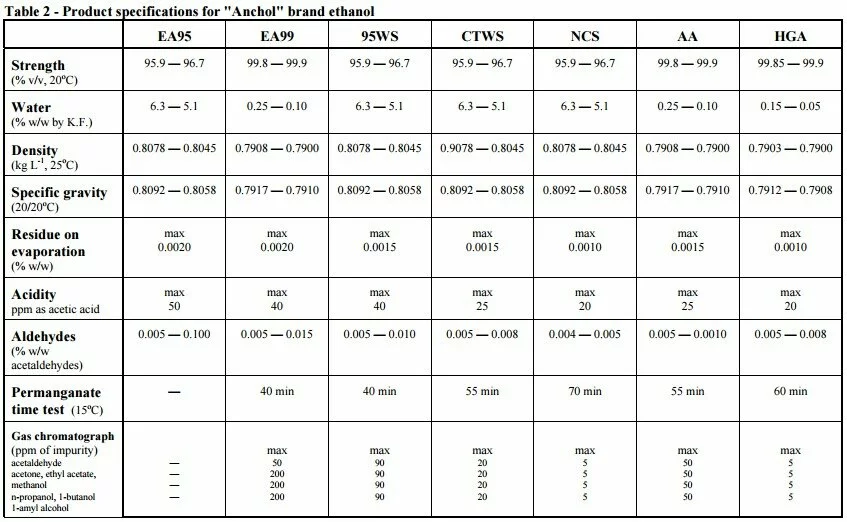

Uses of ethanol derived from whey Ethanol is utilised in New Zealand in products as diverse as potable spirits (vodka, rum etc.) to printing inks and white vinegar. Table 1 summarises the end uses of the eight grades of ethanol produced by Anchor Ethanol.

THE MANUFACTURING PROCESS

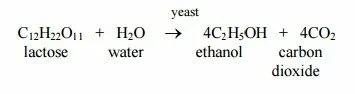

The Anchor Ethanol Distilleries receive serum or deproteinated whey from lactic casein, mineral acid or total milk protein (TMP) production processes. If the whey is derived from lactic casein manufacture the lactose content is only about 4% because about 20% of the lactose in the milk has been converted to lactic acid as a result of the natural fermentation process used. Whey derived from sulphuric acid casein manufacture or TMP production is slightly higher in lactose. The lactose is yeast fermented according to the equation below, and the resultant ethanol is distilled off and then purified to one of eight grades depending on its intended end use.

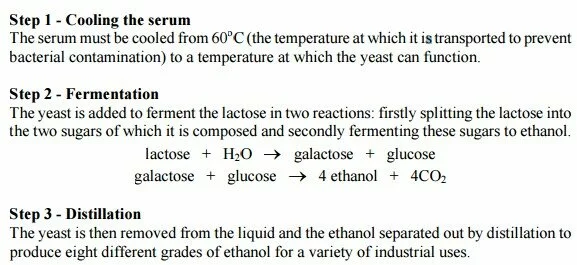

Step 1 – Cooling the serum Serum receipt temperature at the distillery is normally greater than 60o C. At this temperature the serum is essentially free of bacterial contamination, thus the first stage of the process is to cool the serum to the fermentation temperature using a plate heat exchanger. Yeast is added to this cooled serum and pumped to the first of three fermentation vessels.

Step 1 – Cooling the serum Serum receipt temperature at the distillery is normally greater than 60o C. At this temperature the serum is essentially free of bacterial contamination, thus the first stage of the process is to cool the serum to the fermentation temperature using a plate heat exchanger. Yeast is added to this cooled serum and pumped to the first of three fermentation vessels.

Step 2 – Fermentation The fermentation takes about 24 hours, with the fermenting serum passing from one vessel to the next. In-process control involves monitoring the processing flow rate (m3 hr-1) and also serum specific gravity, which declines from about 1.022 kg L-1 to 1.008 kg L-1 as the fermentation progresses. The decline in specific gravity reflects the change of lactose to ethanol with the evolution of carbon dioxide.

The chemistry of the process

Yeast is grown up (or propagated) in separate vessels called ‘Donas’. In the Donas, air is used to promote the growth of yeast biomass growing on the serum. After the serum is cooled, yeast from the Dona vessels is used to inoculate the cool serum.

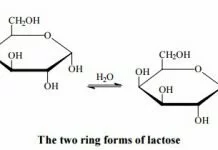

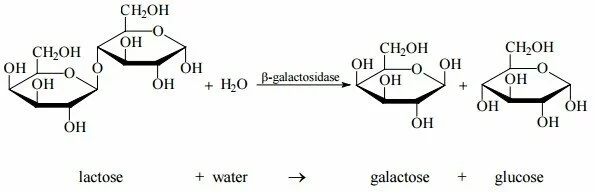

The yeast used is not the one used to make bread or beer but a special lactose fermenting organism called Kluveromyces fragilis. This yeast produces $-galactosidase, the enzyme required to split lactose (a disaccharide) into its component sugars which are glucose and galactose.

The fermentation temperature is determined by the processing speed required, but it is kept as low as possible to minimise bacterial contamination of the process¹ . The maximum conversion of reactants to products is 51%, and this percentage is used as the basis of the fermentation efficiency calculation. Serum has been found to have everything required by the yeast to grow so no further additions to the fermentation are required.

Once the fermentation has been completed yeast is removed from the fermented serum using separators or by decantation. When the yeast has been removed from the fermented serum the liquid is called beer. The beer is stored prior to the extraction of ethanol by distillation.

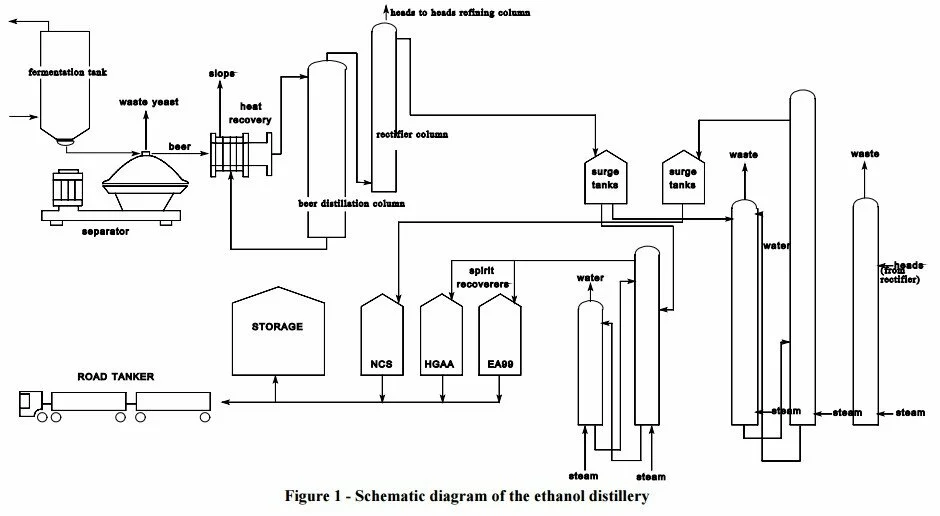

Step 3 – Distillation Figure 1 shows the distillation flow pattern for the Reporoa distillery. The beer enters the process upper left and is fed into the top of the beer column. Ethanol vapour from the top of this column enters the rectifier column from which the primary product (WS 95) is recovered. The WS 95 product is then fed to the anhydrous columns (centre) or to the extractive distillation column (right). Heads (not shown) from the top of the rectifier column are refined in the heads column to the extreme right. The low boiling point impurities are vented to the atmosphere and the recovered ethanol returned to the surge tanks.

The Anchor Ethanol Company produces eight grades of spirit (ethanol) depending on the customer requirements for the product. The grade of the product is determined by the number and type of distillation processes involved in its manufacture. High grade potable spirit (i.e. beverage grade) is made from a ‘white spirit’ grade product using an extractive distillation process. The process involves diluting white spirit grade product with water and redistilling the diluted fluid. The impurities remain in the water phase.

Some of the ethanol is further purified to make an anhydrous product. This is done using one of two processes.

(a) A molecular sieve. In this process a clay-like material which has water-sized holes reversibly absorbs water molecules, but not ethanol molecules. Once the hydrous (i.e. water-containing) ethanol has passed through a bed of this material the bulk of the water has been removed and the ethanol strength has been raised from about 96.3% v/v ethanol to a little in excess of 99.9% v/v ethanol. The water absorbent is regenerated using steam.

(b) Using ethylene glycol. In this process use is made of a high boiling point fluid which strongly absorbs water. Water binds better to ethylene glycol than to ethanol, so the water dissolved in the ethanol can be removed with ethylene glycol in a distillation column. The ethylene glycol is then heated to a higher temperature to boil off the water, and the anhydrous ethylene glycol can then be used to remove water from more ethanol.

After the ethanol has been removed from the beer the waste liquid stream is termed stillage. Spent yeast is either wasted to an effluent treatment system or sold as stockfeed.

The Anchor Ethanol Tirau distillery uses three columns to produce two grades of spirit: WS 95 (white spirit 95%) and EA 95 (ethyl alcohol 95%), the white spirits grade being of better quality. The Anchor Ethanol Reporoa distillery uses a seven column system to produce a further six grades of product (inluding potable and anhydrous products). The properties of the various grades are given in Table 2.

UTILITIES

The use of energy, principally in the form of steam, is minimised wherever possible. Mechanical vapour recompression (MVR) is used to extract the latent heat of vapourisation from the stillage waste. After passing through the MVR tank further heat is extracted from the stillage by the countercurrent passage of stillage against incoming beer. In these ways a substantial component of the plant operating costs are kept to a minimum.

THE ROLE OF THE LABORATORY

The Anchor Ethanol plant at Tirau is ISO 9002 certified, and the certification for the Reporoa plant is currently being finalised. To maintain this standard of quality the laboratory is involved in testing the material at many stages in the process. The raw material, the processing in each fermenter, the separated beer and the final alcohol product are all analysed every two hours and appropriate adjustments made.

The specific gravity of the fluid in each of the fermenters is monitored to give a measure of the fermentation efficiency, i.e. the percentage conversion of lactose to ethanol compared to the maximum theoretical conversion. If the specific gravity is rising, this reflects a deteriorating efficiency, and the processing rate is decreased. If it is static at about 1.008 kg dm-3 this reflects a deteriorating fermentation efficiency, and the ‘side’ is slowed down.

Various other parameters are monitored using appropriate laboratory techniques, including colourimetry and gas chromatography. Every delivery and shipment is sampled, tested and provided with its own Certificate of Analysis, including specialised testing, if required by the end-user.

Written by Ron Hamilton (Anchor Products, Tirau) with editing and summary by Heather Wansbrough.