Marketing Mozzarella Cheese to the Indian housewife

I believe it was the Second World War that helped cola drinks become more popular in Europe and Asia. Colas supplied to American soldiers as part of their ration was bartered for alternative local supplies and that enabled local population to develop the taste for colas. Prolonged wars actually led to building up of residual new markets, which were then serviced and carefully nurtured by the cola companies.

In Europe, during the war for example, American soldiers were buying pizzas in exchange for colas and developed taste and liking for both pizzas and mozzarella cheese. When peace returned and they were back in the US, many soldiers set up their own pizza parlors and in a short time, pizza and cola combination became part of American way of life! Standardization, Specialization, Globalization and American free market entrepreneurial spirit, quickly turned pizza into global fast food! This in turn led to fast growth of demand for mozzarella cheese. Traditional mozzarella cheese used to be made from buffalo milk, in Italy and is characterized by its long stretch and delicious lactic aroma. But because in other western countries, cows were more prevalent, the genuine buffalo mozzarella cheese got replaced subtle with cow milk based ‘pizza’ cheese and later by even cheaper substitutes.

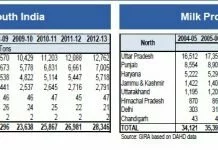

Amul pioneered Cheese in India in 1960 making Cheddar Cheese from buffalo milk and built the cheese market in India brick by brick. India used to consume tons of cottage cheese know as Paneer (Similar to Haloumi), but it has neutral flavor and taste which makes it ideal to absorb the flavor of spices it is cooked with.

Cheese, on the other hand, has distinct different flavor and taste, which to most Indian palates is relatively pungent. However, on few repeated trials or use one develops a taste for cheese. Gradually Cheese, which was a top end food, has penetrated Indian homes, to the extent that its penetration in urban India is close to 37%.

With fast globalizing Indian economy, younger demographics, higher incomes and faster life style, Out-of-Home food consumption was bound to increase. Mass media and exposure to western life style was certain to trigger growth in demand for Cheese, and Mozzarella and Cheddar in Particular.

We therefore decided to setup a dedicated Cheese Plant and also start manufacturing Mozzarella Cheese. Before we went full fledged on mozzarella production, we set up a pilot plant for launch in the market. Surprisingly, a few weeks later I read a comment in a popular business magazine that Amul had started marketing mozzarella cheese, but one does not know where to get it from! I wasn’t very happy reading such a comment and decided to rectify our approach.

Mozzarella cheese and pizzas were not something housewives were very familiar with and hence consumer demand was small and dispersed. For us to scale the product, the challenge was to convert this into a mass market.

At GCMMF, we had recently recruited a dairy technologist and I encouraged her to visit different pizza outlets, taste all possible varieties, read literature and develop a set of recipes for the Indian palette. We encouraged her to localize the recipe by changing some ingredients to give spicy Indian taste. We then got her all the equipment a good chef would need, including an outfit befitting to a top chef. The plan was to advertise in a Newspaper, inviting women folk in the household to enroll in Teach-and-Treat Program in a star hotel. The idea clicked. Within matter of days we have over 100 participants with whom we conducted the first program and the lady officer was thrilled! We immediately planned to scale up the program across several cities of Gujarat.

It wasn’t good enough educating the end customer about concepts of pizza cheese if our own sales and distribution folk did not have the right degree of appreciation for the product. So we decided to bring our sales staff and distributors into this change program. All these encouraged distributors to put in effort to build their retail network for cheese.

We pulled in many of our staff to leave aside their normal job and start conducting ‘teach and treat’ program for cheese! To support them, we focused on creating written manuals & training programs, to help them execute the program independently and effortlessly.

The response was surprisingly good. It was clear that our approach was working, and that our attempts to build a mass market we should include small vendors and shopkeepers. We decide to teach them how to add value in the last mile, and make pizzas from the cheese! So began the next phase of this massive change program, with the recruitment of about sixty “Pizza Consultants“. These were trained not just to execute the ‘teach & treat’ program for retailers, but also exposed to our culture and our shared vision. With only four days of induction, the Pizza Consultants were placed at several locations of importance, and tasked with conducting the ‘teach and treat’ classes. They were also asked to give us written feedback and to identify the best participant to in turn become ‘Pizza Consultants.’

In one and half years, we had conducted about 15,000 ‘teach and treat’ classes pan India, trained nearly a hundred thousand women folk and trained nearly 6,000 retailers to make pizza! Finally, to top it all we made a full 30-second TV commercial to go mass market with the actual Mozzarella cheese product.

Our strategy was to educate the customer and build a base, which could act as a catalyst in the market when we go full-fledged. Unlike many other MNCs, had we gone top down and advertised first, it would most likely have been a bit of a flop-show. Within one year of launch, all the efforts led to sales from practically nothing, to about 120-150 metric tons each month.

Boosted by our success, we wanted to take the program to the next level by making frozen pizzas, utilizing our cold-chain distribution network and distributing along with ice creams. I thought that with over 75,000 ice cream retail outlets (at that time) and a frozen cold chain unique to Amul, we could build frozen pizza market quickly. But, I did not succeed. I had missed an important element to become successful, which was a good quality oven required in the house holds, to convert the frozen pizza into steaming hot pizza – and that was something outside our zone of control. Converting frozen to fresh steaming hot pizza was difficult then, in Indian homes with limited equipment and thus, building a market for frozen pizza remained a dream unfinished!

But these taught, my colleagues and me, great lessons. I am sure that with better quality ovens in India, the day is not far when Amul will successfully be able to market branded packaged frozen pizza for masses!

Mr. BM Vyas took-over as Managing Director of AMUL Co-Op. during expansion and opening up of the Indian economy & globalization in the 90s. In order to take on the competition, he championed Total Quality Management across the dairy value chain in Gujarat. Within a span of 16 years at helm of AMUL, he increased sales of AMUL to eight-folds (from Rs. 9.8 billion to Rs. 80 billion). He steered AMUL to be Asia’s largest fresh Milk processor or No. 1 Dairy Brand in India as well as in Asia Pacific, as per Media Magazine Survey, 2009. Under his leadership; AMUL launched innovative and special Dietary products like Probiotic & Sugar Free Ice Cream, Probiotic buttermilk for the first time in India.

Comments

comments