Indian dairy industry – Past, Present And The Boom Ahead

We have all read or heard sometime in our life that in past India was a land flowing with milk and honey. Yet when we became independent in 1947 milk was scarce and beyond our means. In urban india the per capita consumption was barely 35 kg per year versus a world average of 125 kg.

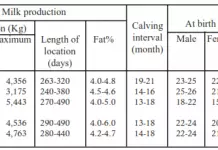

India had some of the best breeds of cattle in the world, cows such as Sahiwal, Red Sindhi, Gir, Kankrej, Ongol and buffallo breeds like Murrah, Mehsani, Banni etc. We had a beautiful tropical weather, fertile land mass, a reasonably good monsoon and five perennial rivers flowing through fertile land and mountains.

With such natural resources bestowed on this country it begs a questions as to what went wrong with dairy farming in India? How a country so rich in milk and honey became devoid of milk?

To answer this question, we must look at the history in a different light.

Traditionally India had some of the best cattle breeders in the world and most high yielding genetic stock. But that is until the British arrived in India. With the advent of British era urbanization around India, major sea ports such as Mumbai. Chennai, Cochin, Kolkata and the national capital Delhi started growing rapidly.

This ever increasing population meant a rising demand for milk resulting into formation of what is now known as “tabelas” or “khattals”, enclosures where cows and buffalos were reared for milk. If one takes a local train from north of Mumbai to South, you can still spot a large number of these enclosures along side the railway tracks. These tabela owners are keen to maximize their profits and they would bring best of the high yeilding buffalos from hinter-land some along with their young calves and within a week they would wean away the calf and send it to slaughter house.

The buffalo will be reared for a few lactation cycles and then disposed off to a slaughter house. The empty slots in the tabela are soon replaced with next best stock purchased from the hinterland.

Since the tabela owners weaned away the calf and sent it to slaughter house, each time a calf is slaughtered, the next best genetic stock was lost because the ‘calf’ is the future cow. Ignorant tabela owners were inadvertently destroying the best genetic stock of the country. By killing the calf of a good buffalo or cow, they were inherently killing the best cow/buffalo of the future! Each time they cycle in next best stock and off to a slaughter house, the country was losing its best genetic pedigree year after year.

This process went on, unchecked for more than a century and not just in Mumbai but in all metros of India. This resulted into a severe loss of high yielding genetic stock and country was left with milch animals with dismal productivity.

In 1946 when Amul came into existence, a new beginning of farmer-owned organized dairy cooperative movement took hold. Till then all of the government milk schemes, were more milk distribution & urban consumer focused rather than on milk production. As the AMUL model grew – providing a fair market access and remunerative prices to the farmers along with services such veterinary care, balanced cattle feed supply, artificial insemination, progeny tested frozen semen – the supplies of milk production and its productivity started going up. For the first time in about 200 years then, someone was trying to stop and reverse almost 1000 year of animal genetic stock deterioration.

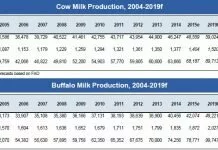

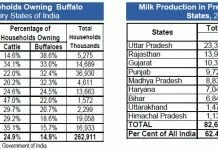

Between mid seventies to nineties, the dairy cooperative movement spread to more than 200 milk producing districts of India with milk production growing at 4 to 5% pa. Even with limited gains on productivity, scarce fodder, frequent draughts the farmers largely dependent on agri-residual feeding and even then India emerged as one of the largest producers of milk in the world. Another startling thing happened – the per capita milk consumption rose and was almost equal to the global average.

Now, if even in such trying circumstances, if milk production could increase from 20 million ton’s in 70’s to 121 million ton now; i.e. almost 6 fold in 40 odd years – why do our bureaucrats in New Delhi, sitting in their plush air conditioned offices doubt that in next ten years the milk production will not grow 7th fold?

This raises some grave doubts about their intent. Claims that Delhi gets tea when Amul milk reaches there from Gujarat but it is not as if any government has done anything to make it happen! My only reply to these statements is, lets not forget the blood sweat and tears of Tribhovandas, Dr. Kurien and Moti bhai Chaudhary. It is their effort, and their’s alone, that today New Delhi gets milk every morning for their tea.

Several studies show that milk production is likely to double and cross 200 Mn. tons by 2020. I am sure this is achievable, with better infrastructure – road connectivity, power supply, faster communication, and more educated milk producers with an ever expanding demand for milk & milk products in this country.

What has been achieved till now has been of the strategic initiatives of Dr. Kurien and the likes but it is sad the despite the availability of technology and new infrastructure, the national institutions responsible for the milk productivity have grossly failed in this area. Even worse to note that instead, such institutions have wasted their time and energy in petty quarrels, idled the funds in bank account to earn interest while the farmers who really need the same are left to face lenders of the last resort. They probably forgot somewhere in the journey that their role was to ensure most effective use of funds to raise milk productivity across the nation.

Modern technologies in the area of Genetic engineering have been successfully applied in countries such as USA, New Zealand, Brazil, Europe and even in Israel and China, while India has failed to deploy them at scales where its effect can be felt. We have lost most valuable time since 2000 till date, wandering in dark and failing to master the technologies for dairy cattle genetic up-gradation. This lost time will cost us dearly, especially if our neighbors decide on making the milk statistics count.

Earlier technologies such as progeny testing were taking decades whereas new genetic engineering can achieve results in much less time and cost. While the national dairy institutions make declarations from time to time, that the country has such a capacity, when it comes to its actual application in the field and the net benefit to a farmer, the results are dismal. Israel, Brazil and even China achieved tech. successes that our national dairy development institutions could not. Who is accountable for such strategic blunders and the exorbitant cost paid? In my humble opinion it is high time that a specific mission be created to spearhead deployment of genetic engineering to supply pre-sexed, high pedigree frozen embryos and semen of proven bulls by importing from countries like Brazil, which is suitable for our indegeneous breeds like the Gir, Kankraj, Ongol, Murrah etc.

Secondly we need to realize that as a nation while our per capita milk consumption is almost at par with the rest of the world, our nation is still suffering malnutrition on a large scale. Health of our women and children is poor especially among the rural and urban poor. We are short on high quality protein intake, but in the name of liberalization we export millions of tonnes of soya, cotton-seed, rap-seed, mustard-seed, all of which contain 30% to 40% of crude protein. Imagine if this was fed to our cows, buffalos or used in poultry this crude protein would have been converted in to highly digestible protein which children of this country needs most. Converting and feeding such meal to our cattle would generate employment in villages, especially of women.

It is argued that export of protein brings in valuable exchange, but reality is that most of it is again spent on import of pulses! Exporting crude protein and importing pulse protein with the costs of transaction and currency – doesn’t make sense to me. Now, don’t count me as anti-globalization or liberalization, I only insist that these phenomena must not hurt the lowest economic-rung of the society and that someone needs to look beyond the urban India that is shining.

Another argument has been that lack of export would affect oilseed prices. But the fact is that the country imports massive volumes of edible oil at negligible import duty. That hurts farmers more especially when world markets are heading south (more often that not these days!).

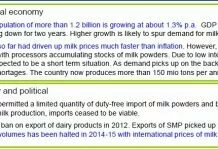

My point is that we should first make enough fodder available locally at an affordable rate. Earlier until the 90’s governments had imposed a levy of 20% on export of protein-meal. This kept the exports in check and ensured meals are available for domestic consumption for dairy and poultry industry at at least 20% cheaper then world market! This not only enabled the country to enhance milk and egg production, but also created employment and keep these local businesses more competitive. But since the 90’s our governments have failed to take right steps to boost availability of fodder, protein meal and now when milk prices go up, the governments resorts to banning exports of milk powders, casein and even go to the extent of importing milk powder.

Import of milk powder and banning of milk products is a knee-jerk reaction when the babus in New Delhi get a kick in their gut, exposing their in capability of having taken any long term consistent policy measures.

For more than a hundred years the Indian dairy industry suffered cattle genocide and only with advent of amul in 1946 did the the wheel start to turn back and in the right direction. If well managed, the next two decades will be golden eras of milk production and productivity gains. Country’s economy is going to boom for the next few decades powered by a young population and hence the market for milk and value added milk products is going to grow hand-in-hand predictably at an unprecedented pace.

Indian food habits vary from region to region in the country. Rice is predominant in east and south while wheat is staple in north and west. But having said that, milk is the most common food all across. Milk has 99% penetration and is considered a wholesome food by every Indian.

The challenge therefore is to make it affordable and available.

Affordability is clearly a result of equaling the supply to the demand. But make no mistake, supply needs to sustainable and local – as an outstripping demand will place huge pressure on milk supplies especially if the supply increments are managed by importing from outside. That would be an unsustainable solution. In order to make milk affordable we urgently need to take measures in the right direction of sustainable increase by leveraging genetic technologies on larger scales – something that the national institutes mantled with the responsibility have failed to do so since 1995.

If we want India to be strong and healthy, tall and smart and every Indian to live 100 year, we need more milk at affordable prices. Not the right-for-food or other such schemes!

Hope you all have a great day and that you find inspiration in every day life.

– B M Vyas