Source: fnbnews.com

Dairy Products Development with Fermentation-Trends

India, world’s largest milk producer, accounting for more than 16% of world’s total milk production, is the world’s largest consumer of dairy products.

The total amount of milk produced has tripled from 23 million tonne back in 1973 to 95 million tonne in 2008. While, the country is expecting a production level of 135 million tonne by 2015, the projected demand for milk by 2021-22 is 180 million tonne which implies that milk production would have to be doubled. Milk production is growing at 3.3% while consumption is growing at 5% leaving a gap between demand and supply.

In order to meet the rapid growing demand and to increase the milk production, Union government has started a Central scheme National Dairy Plan – Phase 1, for a period of 2011-12 to 2016-17. This scheme will be implemented with a total investment of about Rs 2,242 crore. This scheme’s main objective is to help provide rural milk producers with greater access to the organised milk processing sector and thus to bridge the gap between the demand and supply of milk in the country.

The share of the total milk processing capacity by private sector is 44%of total installed capacity of 73 MLPD (Million Litre per Day) in the country. Therefore, the total share of the organised sector, both cooperatives as well as the private sector is barely 12%. What is, therefore, disquieting is that as much as 88% share of the total milk production is commanded by the unorganised sector. In order to promote dairy industry and attract more investment in this sector, government has also reduced the excise duty of 16% to zero on dairy processing machineries.

The untapped potential of the dairy sector is immense and opportunity to set up a new dairy venture is great. And there is vast potential for the export of dairy products, as the cost of milk production in India being the lowest. These factors are attracting huge amounts of investment in dairy processing, manufacturing dairy processing equipment, fruit packaging equipment and equipment for biotechnology related dairy industry.

According to a report by Investor Relations Society (IRS), the size of the Indian dairy industry in both organised and unorganised sectors is expected to double to $140 billion by 2020, on the back of growing demand and rising disposable income. The Indian dairy industry, currently pegged at $70 billion (organised and unorganised), is expected to double by 2020. The society is a global network of investor relations professionals. On the back of a rise in disposable income and strong demand for dairy products, the Indian dairy industry is all set to experience high growth rates in the next 5-6 years. While the dairy industry is growing at a compounded annual growth rate (CAGR) of 15-17%, the value-added products alone are growing way beyond 24%, it said.

Milk is the country’s biggest agricultural produce, contributing 22% to agricultural GDP. Growth in financials of existing domestic players, diversification into dairy sector by other companies, surge in private equity deals, entry of foreign firms in the segment are some of the broad indications that India’s organised dairy industry will remain on growth path at least till 2020.

The operating margins in value-added products are almost two times liquid milk business, thanks to changing consumption pattern due to rapid urbanisation. The milk production alone is expected to cross 200 million tonne by 2016 from the current 125 million tonne.

According to NDDB database, milk production in India has been increased from 128 million tonne in 2011-12 to 132 million tonne in 2012-13, simultaneously per capita monthly consumption expenditure in milk and milk products has been increased from Rs 60 (Rural Area) and Rs 106 (Urban Area) in 2007 to Rs 80 (Rural Area) and Rs 139 (Urban Area) in 2010.

In global ecologic comparisons, milk and dairy intakes are strongly associated with adult height, and many international advisory bodies recommend the consumption of 400–500 ml milk equivalents per day. Soured milk would have invented itself as soon as humankind started milking animals.

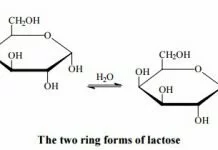

The history of when specific lactose-digesting bacterial cultures were first used and intentionally propagated will never be known with certainty, but residues from ancient fragments of potsherds, apparently designed to act as strainers, have been dated as far back as 8,500 years ago. Such “domesticated” fermentative organisms serve the very useful dual purposes of partial lactose digestion and provision of ?-galactosidase (lactase), which continue to break down lactose after consumption. Both of these attributes would have assisted early humans in tolerating the substantial lactose loads that accompany milk consumption and would otherwise cause seriously debilitating adverse gastrointestinal effects.

In all mammalian species, intestinal lactase, highly active when the young are receiving their mother’s milk, is down regulated in a coordinated manner speculated to be a natural part of weaning the offspring away from mammary feeding so that the mother can initiate a new reproductive cycle. The result is that older offspring and adults become lactose intolerant; they fail to break down the lactose disaccharide, thus causing lactose intolerance but can be rapidly resolved with a lactose-exclusion diet. Thus fermented milk products came in to the picture and became vital part of our daily diet.

Milk is an excellent example of a food having both nutritional and non-nutritional physiological roles in the human diet. Milk proteins not only supply the body with amino acids necessary for the maintenance and growth of body protein, but also give rise, during food manufacture and/or food digestion, to a myriad of protein fragments and large and small peptides that have distinct biological functions.

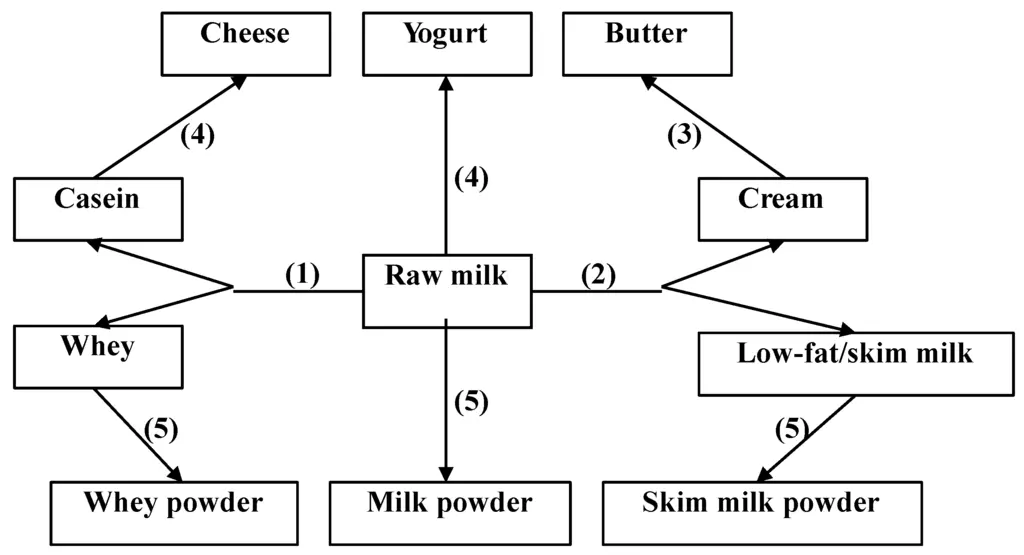

Amino acids released during digestion have regulatory functions or act as precursors for the synthesis of key non-protein metabolites. Such compounds are a rich source of bioactive components for the development of functional foods. Fig.1 enlist the key functional roles of milk proteins, amino acids and bioactive peptides.

Recent Trends in Assessing Protein Quality

An international consensus view has formed that the traditional Protein Digestibility Corrected Amino Acid Score (PDCAAS) method for describing dietary protein quality for humans is being replaced by a method based on true ileal amino acid digestibility and availability and not involving truncation of the score for individual food ingredients (DIAAS ; Digestible Indispensable Amino Acid Score). Milk Protein has high true ileal digestibility value up to 95%. Calculated DIAAS values for whey protein isolate, milk protein isolate and whey protein concentrate are 1.25, 1.31 and 1.10 when compared with soy protein isolate (0.99) and pea protein concentrate (0.93) showed the significant complementary values of milk proteins. Because of their relatively high levels of nutritionally important amino acids, milk proteins are utilised efficiently by humans when given as a sole protein source. Due to high availability of amino acids in milk proteins and their abundant supply, milk proteins are commonly for manufacture of nutritionals – foods designed for specific nutritional purpose.

Novel Techniques to Access Microbial Content to Functionality

Despite health claims linked to the microbial composition of fermented beverages, there is a considerable lack of analyses relating to the microorganisms present and the quantities in which they exist in fermented dairy products. Application of unbiased, standardised techniques shall be used to assess beverages from different geographical regions, and to reach a consensus on the definition of microorganisms which constitute part of any particular product. Fermented dairy foods are naturally fermented, and thus subject to environmental influences, their microbiota can differ significantly, but the application of reliable technology can help definitively identify a core population (or lack thereof), responsible for characteristic traits of the fermented dairy product in question.

The availability of molecular technologies such as culture-independent, high-throughput, sequencing-based microbial analyses, metabolomics and bioinformatics prove particularly useful, and provide a more accurate picture of these populations, surmounting problems associated with relying on phenotypic-based approaches. In-depth molecular studies have the potential to be particularly useful when carrying out analyses across different fermented dairy food with a view to attributing specific desirable or non-desirable sensory and organoleptic characteristics with specific microorganisms present. Such approaches will ultimately facilitate accurate species identification, leading to novel starter design, and the development of products with different and complex flavour profiles. It will also be possible to more effectively monitor the change of proportions of different species throughout fermentation and storage.

Functional Products: Concept to Commercialisation

A fundamental characteristic of breakthrough products is their ability to meet consumer needs, providing added value and benefit for the consumer. In addition, breakthroughs have been defined as products, which may expand or redefine a product category being distinct from existing portfolios. Lifecycles of breakthrough products are typically longer than those of line extensions. Consequently, the development of a breakthrough requires an intricate combination of technological expertise and an awareness of the not so obvious market needs. It may thus be suggested that also the current technology push for functional food development must optimally target the market pull for such breakthrough products.

The selection of appropriate starter strains is the key in efforts to accurately reproduce the desirable characteristics of traditional health-promoting fermented dairy products for mass production (Refer Fig.2). To faithfully reproduce these products and traits, microbes should be sourced from the traditional fermented dairy products, given that these microbes have adapted over thousands of years to their respective environments, and are more likely to function at the appropriate pH, salt concentration, temperature etc.

Such populations also have a history of safe human consumption. Rational strain selection to produce the correct balance of flavour, aroma, texture, acidification, bitterness, speed of fermentation, and the optimum quantity of organic acid, vitamins and minerals is essential, as fermented products that are too sour or bitter, will not meet consumers’ approval.

Over recent years, genetic tools have become available to engineer and select superior starter strains, but legislation currently hinders their industrial use. The inclusion of strains producing antimicrobials, such as bacteriocins, could serve as natural preservatives and help produce a more natural product, while sequential fermentation with yeast, followed by bacteria, could produce a product with the desired physiochemical effects, but without biostabilisation issues created by excessive acidity development.

As stated above, the natural fermentation of these products involves many different strains of bacteria, and sometimes, yeasts. There is an understandable tendency to keep starter formulations simple but, as traditional fermented product show, there are often multiple strains involved, including different species or even microorganisms. From a health perspective, multistrain or multispecies probiotic fermented products may provide greater beneficial effects than monostrain cultures. Unfortunately, however, there is a lack of studies assessing the effects of combining several natural strains on the physiochemical and sensory characteristics of milk or other fermented products. Without such information, it is difficult to accurately reproduce the characteristics of the organic fermented products with one produced by a defined combination of starters, to match the flavour and properties of the original. This is crucial when marketing fermented foods to consumers already familiar with the artisanally produced variant of the product, and if wishing to retain any health-promoting characteristics attributed to the original product.

In spite of the wide range of options available when designing novel health-promoting fermented products, there will always be an attraction for healthy foods derived from natural processes. Applying the solid inoculation matrices of traditional fermented dairy products to new substrates provides a means of generating new fermented dairy products while retaining natural microbial populations. For example, kefir grains have been employed to produce whey and cocoa pulp beverages containing potentially health-promoting strains. Similarly, the cellulosic pellicle of kombucha has been successfully used to ferment milk and other substrates.

The selection of appropriate starter strains is the key in efforts to accurately reproduce the desirable characteristics of traditional health-promoting fermented dairy products for mass production (Refer Fig.2). To faithfully reproduce these products and traits, microbes should be sourced from the traditional fermented dairy products, given that these microbes have adapted over thousands of years to their respective environments, and are more likely to function at the appropriate pH, salt concentration, temperature etc.

Such populations also have a history of safe human consumption. Rational strain selection to produce the correct balance of flavour, aroma, texture, acidification, bitterness, speed of fermentation, and the optimum quantity of organic acid, vitamins and minerals is essential, as fermented products that are too sour or bitter, will not meet consumers’ approval.

Over recent years, genetic tools have become available to engineer and select superior starter strains, but legislation currently hinders their industrial use. The inclusion of strains producing antimicrobials, such as bacteriocins, could serve as natural preservatives and help produce a more natural product, while sequential fermentation with yeast, followed by bacteria, could produce a product with the desired physiochemical effects, but without biostabilisation issues created by excessive acidity development.

As stated above, the natural fermentation of these products involves many different strains of bacteria, and sometimes, yeasts. There is an understandable tendency to keep starter formulations simple but, as traditional fermented product show, there are often multiple strains involved, including different species or even microorganisms. From a health perspective, multistrain or multispecies probiotic fermented products may provide greater beneficial effects than monostrain cultures. Unfortunately, however, there is a lack of studies assessing the effects of combining several natural strains on the physiochemical and sensory characteristics of milk or other fermented products. Without such information, it is difficult to accurately reproduce the characteristics of the organic fermented products with one produced by a defined combination of starters, to match the flavour and properties of the original. This is crucial when marketing fermented foods to consumers already familiar with the artisanally produced variant of the product, and if wishing to retain any health-promoting characteristics attributed to the original product.

In spite of the wide range of options available when designing novel health-promoting fermented products, there will always be an attraction for healthy foods derived from natural processes. Applying the solid inoculation matrices of traditional fermented dairy products to new substrates provides a means of generating new fermented dairy products while retaining natural microbial populations. For example, kefir grains have been employed to produce whey and cocoa pulp beverages containing potentially health-promoting strains. Similarly, the cellulosic pellicle of kombucha has been successfully used to ferment milk and other substrates.

New sequencing technologies have dramatically increased our knowledge on the composition of the human intestinal microbiota in health and disease. In parallel, various omics as well as focussed molecular studies have revealed novel insights in host–microbiome interactions at the cellular and molecular level (Refer Fig. 3). Although these studies are descriptive, advanced microbiota-targeting intervention strategies are being explored, ranging from the selection of novel probiotic strains and synthetic stool substitutes, toward the better monitoring of prebiotic and dietary interventions. It can be envisaged that the efficacy of microbiota interventions will depend on the status of the microbiota of an individual at baseline, but also on genetic and physiological host parameters that determine the capacity to interact with microbes via specific receptors.

There is a wide range of functional foods that were developed recently and many of them are being produced all over the world including probiotic, prebiotic and symbiotic foods. Fig. 4 enlists different types of prebiotic with their sources being used to incorporate in fermented dairy products. Prebiotics are short chain carbohydrates that are non-digestible by digestive enzymes in humans and selectively enhance the activity of some groups of beneficial bacteria. In the intestine, prebiotics are fermented by beneficial bacteria to produce short chain fatty acids. Prebiotics also render many other health benefits in the large intestine such as reduction of cancer risk and increase calcium and magnesium absorption. Prebiotics are found in several vegetables and fruits and are considered functional food components which present significant technological advantages. Their addition improves sensory characteristics such as taste and texture, and enhances the stability of foams, emulsions and mouth feel in a large range of food applications like fermented dairy products. Additionally, food application of bioactive prebiotics, stimulation of the viability of probiotics, health benefits, epidemiological studies, and safety concerns of prebiotics are being studied.

Among these foods, probiotic functional foods are the first choice to exert positive effects on the human health. Probiotic functional foods were divided into dairy probiotic foods and non-dairy probiotic foods. Some of dairy probiotic foods including probiotic ice cream, frozen fermented dairy desserts, probiotic cheese, bioyoghurt, drinking yoghurt, kefir, freeze-dried yoghurt and spray dried milk powder have been employed as possible delivery vehicles for probiotic bacteria.

Probiotics are distinct as live microorganisms which, when administered in sufficient amounts present a health benefit for the host, according to Food and Agriculture Organization of United Nations; World Health Organization – FAO/WHO, 2002. Lactobacillus and Bifidobacterium are the most common probiotic bacterial cells that were used in the production of fermented and non-fermented dairy products. It must conform to certain requirements for a dairy food product to be considered as a valuable alternative for delivery of probiotic bacteria in one hand and for variety of probiotic cultures to use as a dietary adjunct and to exert a positive influence in the other hand.

The culture must be native of the human gastrointestinal tract, having the ability to ferment prebiotics, survive passage through the stomach and small bowel in adequate numbers, be capable of colonising in site of action, and have beneficial effects on human health (Refer Fig.5). In order to survive, the strain must be resistant to acidic conditions (gastric pH 1-4), alkaline conditions (bile salts present in the small bowel), enzymes present in the intestine (lysozyme), and toxic metabolites produced during digestion. In the case of dairy food product to be considered as a valuable alternative for delivery of probiotics, it must match definite necessities such as neutral pH, high enough total solids level, absence of oxygen and near to ambient temperatures. Fig. 5 shows some key clinical effects of probiotic and yoghurt strains.

mentioned before, dairy functional foods beyond basic nutritional value have physiological benefits. In fermentation process, acids such as lactic acid, acetic acid and citric acid are naturally produced. These acids enhance organoleptic qualities as well as safety of food products. Lactic acid bacteria are found to be more tolerant to acidity and organic acids than most of the pathogens and spoilage microorganisms. Some fermented dairy products with detailed consideration are discussed as follows:

1. Probiotic Ice Cream

Probiotic ice cream is produced by incorporation of probiotic bacteria in both fermented and unfermented mix. Lactobacillus and Bifidobacterium are the most common species of lactic acid bacteria used as probiotics for fermented dairy products. The pH of non-fermented ice cream is near to seven which is providing to survive probiotic bacteria. The high total solids level in ice cream including the fat and milk solids provides protection for the probiotic bacteria. Because the efficiency of added probiotic bacteria depends on dose level, type of dairy foods, presence of air and low temperature, their viability must be maintained throughout the product’s shelf-life and they must survive the gut environment. The therapeutic value of live probiotic bacteria is more than unviable cells; therefore, International Dairy Federation (IDF) recommends that a minimum of 107 probiotic bacterial cells should be alive at consumption time per gram per mililitre of product. Studies indicate, the bacteria may not survive in high enough numbers when incorporated into frozen dairy products unless a suitable method is used against freeze injury and oxygen toxicity. The physical protection of probiotics by microencapsulation is a new method for increasing the survival of probiotics. Lactobacillus casei (Lc01) and Bifidobacterium lactis (Bb12) have the highest resistance to simulated acidic, alkaline and ice cream conditions in comparison with other probiotic strains, making them suitable probiotic strains for use in probiotic ice cream.

2. Probiotic Cheese

There are two ways for development of probiotic cheese: in the first step, the manufacturing processes of cheese products have to be modified and adapted to the requirements of probiotics and in second step, appropriate probiotic strains are to be applied or new cheese products have to be developed. The proteolytic and lipolytic properties of the probiotic bacterial cells have important effects on taste and flavour of the probiotic cheese. Antagonism between bacteria is often based on the production of metabolites that inhibit or inactivate more or less specifically other related starter organisms or even unrelated bacteria. Cheese provides a valuable vehicle for probiotic delivery, due to creation of a buffer against the high acidic environment in the gastrointestinal tract, and thus creates a more favourable environment for probiotic survival throughout the gastric transit, ought to higher pH. The presence of the prebiotics inulin and oligofructose can promote growth rates of bifidobacteria and lactobacilli, besides increased lactate and short chain fatty acids production in petit-suisse cheese.

3. Probiotic Yoghurt

The conventional yoghurt starter bacteria, L. bulgaricus and Streptococcus thermophilus, do not have ability to survive passage through intestinal tract and consequently so, they are not considered as probiotics. But the addition of L. acidophilus and B. bifidum into yoghurt can add extra nutritional and physiological values. Heat treated homogenised milk with an increased protein content (3.6–3.8%) is inoculated with the conventional starter culture at 45°C or 37°C and incubated for 3.5 and 9 h, respectively. The probiotic culture is added prior to fermentation simultaneously with the conventional yoghurt cultures or after fermentation to cooled (4°C) product before packaging. The survival of probiotic bacteria in fermented dairy products depends on the chemical composition of the fermentation medium (e.g. carbohydrate source), final acidity, milk solids content, availability of nutrients, growth promoters and inhibitors, strains used, interaction between species present, culture conditions, concentration of sugars (osmotic pressure), dissolved oxygen (especially for Bifidobacterium spp.), level of inoculation, incubation temperature, fermentation time and storage temperature.

The ‘overacidification’ is prevented to a limited extent by applying ‘good manufacturing practice’ and by using cultures with reduced ‘overacidification’ behaviour. The inhibition of bifidobacteria in probiotic yoghurt is due to antagonism effects among starter bacteria rather than hydrogen peroxide or organic acids. The ideal procedure for probiotic yoghurt manufacturing is growing the Bifidobacterium spp. separately, followed by washing out of free metabolites and the transfer of the cells to the probiotic yoghurt. Oxygen toxicity is a critical problem for Bifidobacterium spp. because they are strictly anaerobic. Low initial oxygen content in milk obtain the low redox potential required in the early phase of incubation to guarantee Bifidobacteria growth. Oxygen easily dissolves in milk during yoghurt production and also permeates through packages during storage. It has been suggested to inoculate S. thermophilus and Bifidobacterium simultaneously during fermentation to avoid the oxygen toxicity problem. S. thermophilus has a high oxygen utilisation ability, which results in reduction of dissolved oxygen in probiotic yoghurt and an enhancement in viability of bifidobacteria.

4. Probiotic Milk

Acidophilus milk production, the milk is heated at 95°C for 1 h or at 125°C for 15 min. Such a high heat treatment stimulates the growth of Lactobacillus acidophilus by providing denatured proteins and released peptides. High-heat-treated milk is cooled to 37°C and kept at this temperature for a period of 3-4 h to allow any spores present to germinate. Then, milk is re-sterilised to destroy almost all vegetative cells. Unless skimmed milk is used, the heat-treated milk is homogenised and cooled down to inoculation temperature (37°C). Lactobacillus acidophilus is added as active bulk culture. The level of inoculation is usually 2-5% and the inoculated milk is left to ferment until pH 5.5-6.0 or ~1.0% lactic acid is obtained, with no alcohol. The fermentation takes about 18-24 h under inactive conditions. After the fermentation, the number of viable Lactobacillus acidophilus colonies is about 2-3×109 cfu mL-1, but this number decreases up to consumption time. Following fermentation, the warm product is rapidly cooled to

Nutritional Benefits of Fermented Dairy Products

The following describes some of the proposed health benefits of consumption of fermented/probiotic dairy products:

1.Alleviation of Lactose Intolerance

The inability of adults to digest lactose, or milk sugar, is prevalent worldwide. Consumption of lactose by those lacking adequate levels of lactase produced in the small intestine can result in symptoms of diarrhoea, bloating, abdominal pain and flatulence. Milk with cells of L. acidophilus aids digestion of lactose by such persons. Yoghurt was found to be helpful in the digestion of lactose because the lactic acid bacteria used to make yoghurt produce lactase and digest the lactose.

2.Protection against Gastrointestinal Infection

Viable lactic acid bacteria interfere with the colonisation and subsequent proliferation of food-borne pathogens, thus preventing the manifestation of infection. L. bulgaricus, L. acidophilus, S. thermophilus and B. bifidum have been implicated in this effect. The beneficial effects of lactic acid bacteria and cultured milk products have also been attributed to their ability to suppress the growth of pathogens either directly or through production of antibacterial substances. Replenishing the flora with normal bacteria during and after antibiotic therapy seems to minimise disruptive effects of antibiotic use. Probiotics have been reported to be effective in prevention of various gastrointestinal infections, rotavirus infection, traveller’s diarrhoea and antibiotic-induced diarrhoea.

3.Anti-Carcinogenic Effect

Anti-carcinogenic effects of yoghurt and milk fermented with L. acidophilus have been reported in mice. Different potential mechanisms by which lactic acid bacteria exert antitumour effects have been suggested such as changes in faecal enzymes thought to be involved in colon carcinogenesis, cellular uptake of mutagenic compounds, reducing the mutagenicity of chemical mutagens and suppression of tumours by improved immune response.

4.Immune System Stimulation

The immune system provides the primary defence against microbial pathogens that have entered our bodies. The immunostimulatory effect of yoghurt is due to its bacterial components. Cytokine production, phagocytic activity, antibody production, T-cell production etc. are increased with yoghurt consumption or with lactic acid bacteria.

5.Lowering of Serum Cholesterol

Fermented milk products show hypocholesteraemic effect. Intake of large quantities of fermented milk furnishes factors that impair the synthesis of cholesterol. L. acidophilus has exhibited the ability to lower serum cholesterol levels.

6.Alleviation of Constipation

Constipation is a common problem in subjects consuming Western diet and also in elderly people. Fermented dairy products containing lactobacillus (L. acidophilus NCDO 1748, L. casei Shirota and Lactobacillus GG) preparation and fermented milks shows alleviation of constipation.

7.Antihypertensive Activity

Casein hydrolysate, produced by an extracellular proteinase from L. helveticus (CP790) has antihypertensive activity. Two antihypertensive peptides have been purified from sour milk fermented with L. helveticus and Saccharomyces cerevisiae. These two peptides inhibit angiotensin-converting enzyme that converts angiotensinogen I to angiotensinogen II, which is a potent vasoconstrictor. Consumption of certain lactobacilli, or products made from them, may reduce blood pressure in mildly hypertensive people.

8.Antiallergenic Qualities

Probiotics help to prevent allergic reactions in individuals at high risk of allergies, such as food allergies. Probiotic bacteria help to reinforce the barrier function of the intestinal wall, thereby preventing the absorption of some antigens.

9.Functional Bio-Peptides

Fermented produce are a source of bioactive peptides, released through fermentation by proteolysis cultures, and linked with many potential health benefits including digestive, endocrine, cardiovascular, immune and nervous system related ones.

10.Improved detoxification

The presence of glucuronic acid, one of the primary metabolites in kombucha, is believed to improve detoxification by binding toxin molecules and aiding excretion through the kidneys, and it is this acidic composition that is most associated with the reputed health properties of kombucha, rather than a microbial-gut interaction.

Emerging Trends for Fermented Dairy Products

The global functional beverage market is a growing sector of the food industry as modern health-conscious consumers show an increasing desire for foods that can improve well-being and reduce the risk of disease. The development of functional probiotic foods is increasing, as their market increases day by day, although the consumer’s information about these foods is increasing without relation to gender, age, and educational or economic levels of the consumers. The therapeutic effect of a functional probiotic food may depend on the consumer’s characteristics and the type of carrier and enrichment considered.

Cultured dairy products have been providing vital importance in the human diet.

Some of its challenges

Careful selection of specific strains combined with proper production and handling procedures will be necessary to ensure that desired benefits are provided to consumers.

Most suitable candidate organism for fermentation, select different protective and carrier media, evolve a suitable technology to design foods which contain and maintain large populations of viable bio-active organisms during processing and post-harvest processing periods and have longer shelf life.

There needs to be a consensus with respect to what constitutes the natural microbiota of specific fermented dairy product, a description of which are essential for fermentation, and the contribution of each microbe to the final composition.

- Characterization of the relationship between microorganisms, particularly between bacterial and yeast populations. The influence of containers, substrates, metabolites and enhancements on the organoleptic qualities and fermentation kinetics need to be evaluated.

- Increasing pressure to identify and confirm proposed health claims for the consumer.

- Considering the costs of development and clinical trials, innovation in the functional food market may need to become a collaborative effort between industry partners and academia.

- The obvious hurdle is consumers’ willingness to accept an unfamiliar product, with optimum nutrition and flavour development. It has been shown that taste, price and base nutritional composition are more important than functional properties.

- Study the mechanisms of action of probiotics and prebiotics in the GI tract, and develop diagnostic tools and biomarkers for their assessment.

- To evaluate the role of immunological biomarkers and probiotic applications thereof.

- To study GI diseases, GI infections and allergies in different population groups.

- To address trade-offs, and to ensure the stability and viability of probiotic product.

Emerging markets for fermented dairy products

Food service institutional market: It is growing at double the rate of consumer market

Defence market: An important growing market for quality products at reasonable prices

Ingredients market: A boom is forecast in the market of dairy products used as raw material in pharmaceutical and allied industries

Parlour market: The increasing away-from-home consumption trend opens new vistas for ready-to-serve dairy products which would ride piggyback on the fast food revolution sweeping the urban India.