MANUFACTURE AND USE OF CHEESE PRODUCTS

Cheese is the most complex of the dairy products, involving chemical, biochemical and microbiological processes. The steps in all cheese making include milk acidification, milk coagulation, whey removal, packaging and storage. Most cheese making also includes heating the cheese curd and salting the curd. Even slight changes in these processes can lead to significant differences in the final cheese. Control of these has been crucial in the transformation of cheese making from an art or craft to a skilled large scale technological operation that is constantly undergoing minor shifts to accommodate the changing raw material (milk) and the increasing range of custom-made cheese types and styles. Cheddar, Mozzarella, Gouda and Egmont are the cheese varieties made in greatest quantities and make up the bulk of our export cheese.

INTRODUCTION

Cheese manufacture is one of the classical examples of food preservation, dating from 6000-7000 BC. Preservation of the most important constituents of milk (i.e. fat and protein) as cheese exploits two of the classical principles of food preservation, i.e. lactic acid fermentation and reduction of water activity through removal of water and addition of salt (NaCl). The establishment of a low redox potential as a result of bacterial growth contributes to the storage stability of cheese.

CHEESE VARIETIES

There are more than 400 varieties of cheese produced throughout the world, created by differences in milk source (geographic district or mammalian species), fermentation and ripening conditions as well as pressing, size and shape. Most of the cheese types that are produced today originated many centuries ago within smaller communities and are thus named, for example, Camembert and Brie from France, Gouda and Edam from the Netherlands, Cheddar and Cheshire from England, Emmentaler and GruyËre from Switzerland, Parmesan and Gorgonzola from Italy, and Colby from the USA; others are named for some aspect of their manufacture, e.g. Feta from Greece, processed cheese (best known as the cheese slices that go on hamburgers) from the USA, and Mozzarella from Italy; other names are more generic, e.g. cottage cheese from the USA.

THE NEW ZEALAND CHEESE INDUSTRY

New Zealand is the second largest exporter of cheese in the world. We manufactured more than 250 000 tonnes (equivalent to 250 million 1 kg blocks) of cheese from 2.5 billion litres of milk in 1997. Over 200 000 tonnes of this was exported. Nearly half of the cheese produced was Cheddar-type, with the remainder being Mozzarella (for pizzas), Gouda and Egmont, as well as many other varieties. Closely related products such as yoghurt, cottage cheese and cream products are also manufactured, mainly for local consumption. Much of the cheese exported from New Zealand is sold for processed cheese (fast-food outlets), as an ingredient cheese for the fast-food market (pizzas), for cheese powders (flavours for snacks, soups etc.) and for cheese sauces.

There are many variations of a particular type of cheese. Each customer for New Zealand cheese has different and critical requirements in terms of colour, flavour, texture, aroma and chemical composition. The cheese industry relies on an innovative and wide-ranging team of technologists and scientists in order to meet the demands of the market place for consistent product characteristics that meet the customer requirements. In order to maximise the returns to the dairy farmers (the owners of the dairy manufacturing industry), the balance between the different cheese varieties and styles produced for the export market shifts according to the demands of the customers and the price that can be obtained.

THE PRINCIPLES OF CHEESE MAKING

The basic principles of cheese-making are the same for nearly all varieties of cheese. The manufacture involves the removal of water from milk with a consequent six- to tenfold concentration of the protein, fat, minerals and vitamins by the formation of a protein coagulum that then shrinks to expel “whey”. The processes involved are: acidification, coagulation, cooking, salting, dehydration or syneresis, moulding (or shaping) and pressing, packaging and maturation or storage.

CHEESE MANUFACTURE

The general manufacturing protocol for most cheese varieties is outlined in Figure 1. The manufacture of most varieties of cheese involves the following.

Pasteurization of the milk kills nearly all the microorganisms present, including the harmful pathogenic bacteria that cause diseases, such as tuberculosis and leptospirosis, and other undesirable microorganisms, such yeasts and coli forms, that may alter the cheese characteristics by producing carbon dioxide and undesirable proteolysis.

2 Acidification of the milk is important for the proper release of whey from the cheese curd and to control the growth of many undesirable bacteria. It is usually accomplished by the addition of lactic acid bacteria that convert lactose to lactic acid. Most varieties of cheese cannot be made without the addition of a “starter” which is a culture of carefully selected lactic acid-producing bacteria. The special starter cultures are identified and distributed in deep frozen form by the New Zealand Dairy Research Institute to the different cheese plants. The large volumes of starter required for cheese making are made in special bulk starter fermentation pots in which the milk is heat treated to destroy unwanted bacteria, spores and phages and cooled to about 22°C, a temperature suitable for starter growth. The frozen starter is mixed in and fermentation continues for about 6 to 16 hours.

and semi-hard cheeses. (Taken from Byland)

(This process is similar to that used for yogurt manufacture.) The amount of starter required varies for the different cheese varieties but, for Cheddar, this is normally between 1.25 and 2.0% of the cheese milk. The amount of lactic acid produced and the moisture in the finished cheese regulate and control the subsequent rate of the biochemical changes that take place during the ripening or maturation of the cheese.

3. Coagulation of the casein fraction of the milk to form a gel can be achieved by lowering the milk pH and the addition of “rennet”, a mixture containing a specific proteolytic enzyme. The most commonly used rennet contains the enzyme chymosin, either as an extract of calf abomasum or as the recombinant product. Other types of rennet are derived from other animal sources, microorganisms or plants.

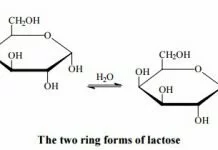

The four main groups of caseins in milk are the αs1-, αs2-, β- and κ-caseins. These phosphoproteins are held together by microclusters of calcium and phosphate and exist in milk as micelles of about 100 nm in diameter containing hundreds of molecules of each type of casein. The more hydrophobic regions of these phosphoproteins are believed to be located inside the micelle with the more hydrophilic regions of κ-casein on the outside. The negatively charged carboxy-terminal of the κ-casein molecules is thought to protrude ‘hair-like’ from the micelle and repel other casein micelles (charge stabilisation).

In addition to this, the hair-like macropeptide portions of κ-casein are unable to interpenetrate (steric stabilisation). These two mechanisms are thought to enable the micelles to stay in solution as colloidal particles. The addition of rennet (includes any of a range of acid proteinases) leads to the partial proteolysis of κ-casein by cleavage at the Phe105-Met106 bond.

The release of the hydrophilic carboxy-terminal peptide (glycomacropeptide) results in destabilisation of the micelles which become less negatively charged and more hydrophobic. These micelles then aggregate (in the presence of calcium and at a temperature above 15C) to form a coagulum. A rennet coagulum consists of a continuous matrix of strands of casein micelles, which incorporate fat globules, water, minerals and lactose and in which microorganisms are entrapped (Figure 2).

Syneresis, or shrinking, of the coagulum is largely the result of continuing rennet action. It causes loss of whey, and is accelerated by cutting, stirring, cooking, salting or pressing the curd, as well as the increasing amount of acid produced by the starter, and gradually increases during cheese making. As a result, the cheese curd contracts and moisture is continuously expelled during the cooking stages.

Salt is added to cheese as a preservative and because it affects the texture and flavour of the final cheese by controlling microbial growth and enzyme activity. The salt can be added either directly to the curd after the whey is run off and before moulding or pressing into shape, or by immersing the shaped cheese block in a salt brine for several days following manufacture. Addition of salt to the cut curd draws more whey from the cheese curd and some of the salt diffuses into the curd. The pH of the curd, the contact time and the salt particle size and structure are all important in determining how much salt is absorbed by the curd Salt is also involved in physical changes in cheese protein solubility and conformation, which influence cheese rheology and texture. Another important function of salt in cheese is as a flavour or a flavor enhancer.

Curd manipulation

(i) Heat treatments. The application of heat to cheese curd at any of several different times during the manufacture of particular cheese varieties, such as Cheddar, Mozzarella or Emmentaler, is to selectively stop the growth of certain types of bacteria and consequently influence the maturation pathway of the cheeses. It also alters the composition and texture of the cheese by increasing the syneresis without increasing the acidity.

(ii) Stretching the curd is an important operation for several kinds of cheese, in particular the pasta filata style, Mozzarella being the best known. Traditionally the curd was immersed in hot (about 80C) water, and the fluid mass of cheese was pulled into strands to align the protein fibres and then poured into a container to cool. It was then immersed in brine. Large scale production means that special machines (Figure 3) are used for stretching.

Figure 2

Diagram showing the action of rennet on the casein micelle. The enzyme in rennet cleaves the κ-casein releasing a large peptide. The surface of the micelle changes from being hydrophilic and negatively charged to hydrophobic and neutral. As a consequence the micelles aggregate to trap fat globules and microorganisms in the developing curd.

Figure 3A.

Flow diagram for the mechanized production of Mozzarella cheese. (Taken from Byland)

- Cheese vat

- Cheddaring machine

- Screw conveyer

- Cooker/stretcher

- Dry salting

- Multi-moulding

- Hardening tunnel

- De-moulder

- Brining bath

- Palletiser

- Store

- Mold washing

Figure 3B.

Details of the cheddaring machine as used for Mozzarella cheese manufacture. (Taken from Byland)

- De-wheying screen

- Stirrer

- Conveyer

- Curd mill

Figure3C.

- Continuous cooker-stretcher for Pasta Filata types of cheese. (Taken from Byland)

- Feed hopper

- Container for controlled temperature water

- Contra rotating augers

- Screw conveyer(iii) Cheddaring is a mild form of stretching in which the cheese curd is piled up and held warm so that it flows under the force of gravity. It is periodically turned to flow again. The pH of the curd falls during this process and whey continues to exude. Again, in large scale manufacture, this is done in large machines (Figure 4)

Figure 4A.

Flow diagram for the mechanised production of Cheddar cheese. B.Details of the cheddaring machine as used for Cheddar cheese manufacture. (Taken from Byland)

- Cheese vat

- Cheddaring machine

- Block former and bagger

- Vacuum sealing

- Weighing

- Carton packer

- Palletiser

- Ripening store

Figure 4B.

Details of the cheddaring machine as used for Cheddar cheese manufacture. (Taken from Byland)

1 De-wheying screen

2 Whey sump

3 Agitator

4 Variable speed conveyers

5 Optional agitators

6 Curd mill

7 Dry salting system

(iv) Washing the curd either in the cheese vat or after dewheying helps remove more lactose which changes the pH of the cheese. It also reduces syneresis and is important in the manufacture of cheeses such as Colby, Gouda and Egmont.

7. Molding. The formation of the final cheese shape into spheres, flattened spheres,discs, cylinders or rectangular blocks is traditional but for some varieties, e.g. Camembert, it affects the maturation pathway. Some cheeses are pressed in moulds (nowadays made of plastic or stainless steel) under the whey for a short time whereas others are compressed at high pressures for several hours.

Maturation or ripening. The ripening of cheese involves three major biochemical events.

(i) Glycolysis: Lactose is metabolised to lactic acid, which may then be catabolised (broken down into smaller molecules) to form acetic and propionic acids, carbon dioxide, esters and alcohol by the enzymes of the microorganisms in the milk, including the added starter.

(ii) Lipolysis: The lipids are broken down to form free fatty acids, that may then be catabolised to form ketones, lactones and esters by natural milk enzymes and those that are added to create the flavour in particular cheese varieties, e.g. Romano, Blue Vein and Feta cheese.

(iii) Proteolysis: Proteins (caseins) are gradually broken down to form peptides and amino acids by the enzymes of the coagulant, the natural milk enzymes and the enzymes of the starter bacteria and other added microorganisms, e.g.moulds such as Penicillium camemberti used in the manufacture of Camembert and Penicillium roqueforti used in the manufacture of blue-veined cheeses such as Roquefort and Stilton. The enzymes of these mould species typically result in a high level of proteolysis in these cheese types.

The amount of acid present has a marked effect on the level of proteolysis seen in the resultant cheese. The activity of the coagulant enzyme, the amount of enzyme remaining in the curd and, as a consequence, the amount of proteolysis are dependent on the amount of acid produced in the initial stages of cheese making.

The pH also controls the level of moisture, which in turn affects proteolysis in the cheese. The final pH of the curd and the rate of pH decline determine the extent of dissolution of colloidal calcium phosphate from the curd. This modifies the susceptibility of the caseins to proteolysis during manufacture and influences the rheological properties (such as texture) of the cheese. The breakdown of the proteins to peptides (proteolysis) transforms the rubbery and flavorless cheese curd into a cheese that has a desirable texture and flavour.

Further proteolysis produces amino acids and the further biochemical glycolysis and hydrolysis result in the formation of amines, aldehydes, alcohols and sulphur compounds that add to the flavour of the cheese.

Packaging. Many cheeses are made and matured in large blocks (e.g. 20 kg) and they are exported as such. When they are to be sold in supermarkets, they are usually cut into appropriate size blocks and either shrink wrapped in an atmosphere of carbon dioxide, which dissolves into the body of the cheese, or vacuum sealed in a special “top-and-bottom” “webbed” package. The subsequent anaerobic environment prevents mould growth on the cheese surface. Many cheeses, such as the Brie and Camembert, are ready for sale at maturation and are packaged in special aerating wrapping and in porous boxes.

MECHANISED CHEESEMAKING

In recent years, mechanised equipment has been developed for the varieties of cheese made in New Zealand. An exclusively New Zealand developed process is the Cheddarmaster system. This comprises a draining belt, to separate the whey from the curd, and a Cheddar tower. The draining belt is now also used for most other varieties.

THE CHEDDAR PROCESS

A flow chart of the mechanised production of Cheddar cheese is outlined in Figure 4. A brief description of the New Zealand Cheddar process is as follows. Whole milk is standardised to a protein to fat ratio of 0.80 (resulting in a typical milk composition of 4.24% fat, 3.38% protein and 4.85% lactose) and pasteurised prior to cheese manufacture.

The temperature of the milk is brought to 32C prior to the addition of starter and rennet (in the ratio 150 mL/1000 L of milk). The milk is allowed to coagulate and this takes approximately 30-40 min. The coagulum is then cut into small cube-shaped particles (approximately 9 mm x 9 mm) and the temperature of the vat is increased to the desired cooking temperature (38C).

Approximately 2.5 hours after the addition of rennet, the vat contents are pumped on to the perforated draining belt. There, the curd moisture is reduced from approximately 65 to 55% before the curd is transferred in an air stream to the top of the cheddaring tower. Alternatively the curd from the vats can be sent to a “cheddaring machine” (Figure 4) where draining, cheddaring, salting and mellowing all take place.

At this point, the acidity has increased considerably and the pH has dropped from 6.6 (at the start of manufacture) to 6.2. During the cheddaring stage, the curd undergoes considerable change. The particles lose their identity and start to bond together under the influence of further development of acidity. During this stage, the moisture content of the curd drops from 55 to approximately 42%.

When the pH has reached 5.3-5.4, the curd is ready for milling and salting. The curd, on discharge from the cheddaring tower, passes through a mill on to a second belt similar to the draining belt, after which salt is applied to the curd. The salted curd is then pressed under vacuum (in a block former) into 20 kg blocks, wrapped in plastic film and cooled to 18C within 24 hours. It is then stored at 10C to allow it to mature. The original milk, containing about 4.5% fat and 86% moisture, has now been reduced to a cheese product containing approximately 37% fat and 33% moisture.

THE MOZZARELLA PROCESS

A flow chart of the mechanized production of Mozzarella cheese is outlined in Figure 3.Whole milk is standardized to a protein to fat ratio of 1.46 (typically resulting in a milk composition of 2.37% fat, 3.47% protein and 5.01% lactose) and pasteurized prior to cheese manufacture. The temperature of the milk is brought to 33C prior to the addition of starter (4%) and held at this temperature for 65 min, when the pH falls from 6.6 to 6.3. At this point rennet is added to the milk. The milk is then allowed to coagulate and this takes approximately 30 min. The coagulum is then cut into small cube-shaped particles (approximately 9 mm x 9 mm) and stirred while the temperature of the vat is increased to the desired cooking temperature. Approximately 2.5 hours after the addition of the starter, when the pH has fallen to 5.9, the whey is drained, and the curds milled, dry salted and then conveyed to the cooker/stretcher. The curd is cooked at 60-65C and stretched to obtain the elastic and stringy character of Mozzarella cheese. The cheese is then “hooped” into 10 kg moulds and cooled. The following day, the cheese is wrapped in a plastic film and stored at temperatures between -2 and 5C.