Source: bangaloremirror.com

Villages can become the source of biogas for sustenance as well as supply to urban India, says IISc scientist

Estimating that India’s soft non-woody biomass production can reach a whopping 1.5 billion tonnes a year, a senior scientist from the Indian Institute of Science (IISc) has said the huge biomass generation could be used through cooperatives – on the lines of the milk cooperatives – to sustain the entire country with biogas for domestic and industrial use.

Soft, non-woody biomass is the residue of high-energy crops (like sugarcane and maize), as well as food, industrial and animal wastes. Non-woody biomass has gained significance in recent years opening possibilities of applying technologies to develop fuels to replace the rapidly diminishing fossil fuels.

Chief research scientist at IISc’s Centre for Sustainable Technologies (CST) Prof HN Chanakya said at the 103rd Indian Science Congress that about 100 million farm families in rural and semi-urban India are a dispersed source of soft biomass with immense potential for small-scale sustainable energy in the form of biogas for domestic needs.

He said biomass can be collected, segregated, transported and distributed to people in rural and semi-urban India through cooperatives, just like the milk cooperatives which have recorded a huge success in the country.

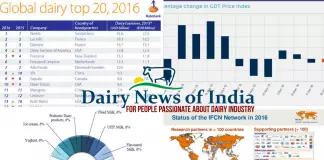

The milk cooperative structures consist of a dairy cooperative society at the village-level affiliated to a milk union at the district level. This, in turn, is part of a milk federation at the state level. The milk collection is done at the village dairy society; milk procurement and processing at the district milk union; and the marketing of milk products is done at the state milk federation.

A similar structure could be devised for the distribution of non-woody biomass to rural and semi-rural areas, where people can be trained to convert biomass residues first to biogas that can meet the demand, and then to a variety of value-added products to boost cash returns.

“These value-added products can be further processed at the village-level to create livelihoods and sustainable incomes within the villages, while on the other hand provide multiple points of value-addition and employment,” Chanakya said.

“The village-based biogas plants, when fed with cut banana leaf sheaths, leaves or rachis, convert 50 per cent of the material to biogas – meeting the immediate need for sustainable energy,” he said.

Comments

comments